[CELLiST] Poloxamer for Cell Culture

페이지 정보

작성자 ajinomo 조회 653 작성일 24-09-19 16:08본문

Dear Valuable Customer,

Thank you for showing interest in our media products and for the opportunity to address the challenges you face. Based on our expertise, we provide here comprehensive information and guidelines on using poloxamer in your processes with our media. CELLiST Solution Center, is committed to supporting your success and we are looking forward to continuing our collaboration.

1. Information on CELLiST media

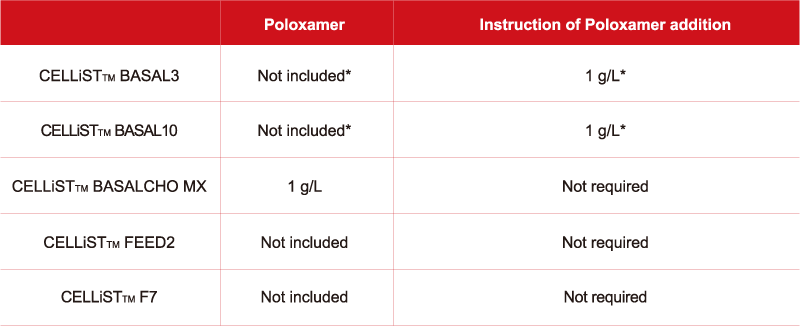

Please refer to the following table for a summary of CELLiST media and poloxamer usage. Table 1. Poloxamer usage in CELLiST media

* New product, BASAL3P and BASAL10P (including poloxamer, 1 g/L) will be released soon

Note: Ajinomoto CELLiST Korea uses Kolliphor® P188 Bio from BASF for media production.

2. Why Poloxamer?

2.1. General Information

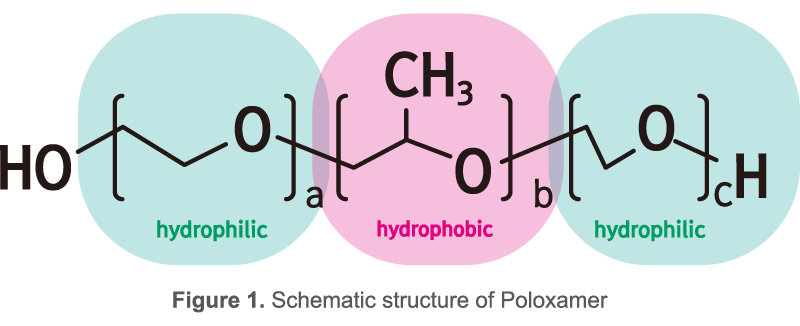

Poloxamers are nonionic triblock copolymers consisting of a central hydrophobic block of polypropylene oxide (PPO) flanked by two hydrophilic blocks of polyethylene oxide (PEO). Their general structure is represented as PEO-PPO-PEO, illustrated on the left1. The term "poloxamer" was coined by BASF inventor Irving Schmolka, who obtained the patent for these materials in 19732. Poloxamers are valuable tools in cell culture for protecting cells, improving viability, and stabilizing biopharmaceuticals. Due to their amphiphilic structures, these polymers possess surfactant properties, making them valuable for various industrial applications, including biopharmaceutical production.

1 Bollenbach et al., Int. J. Pharma. 620, 121706.

2 US3740421A

2.2. Shear stress

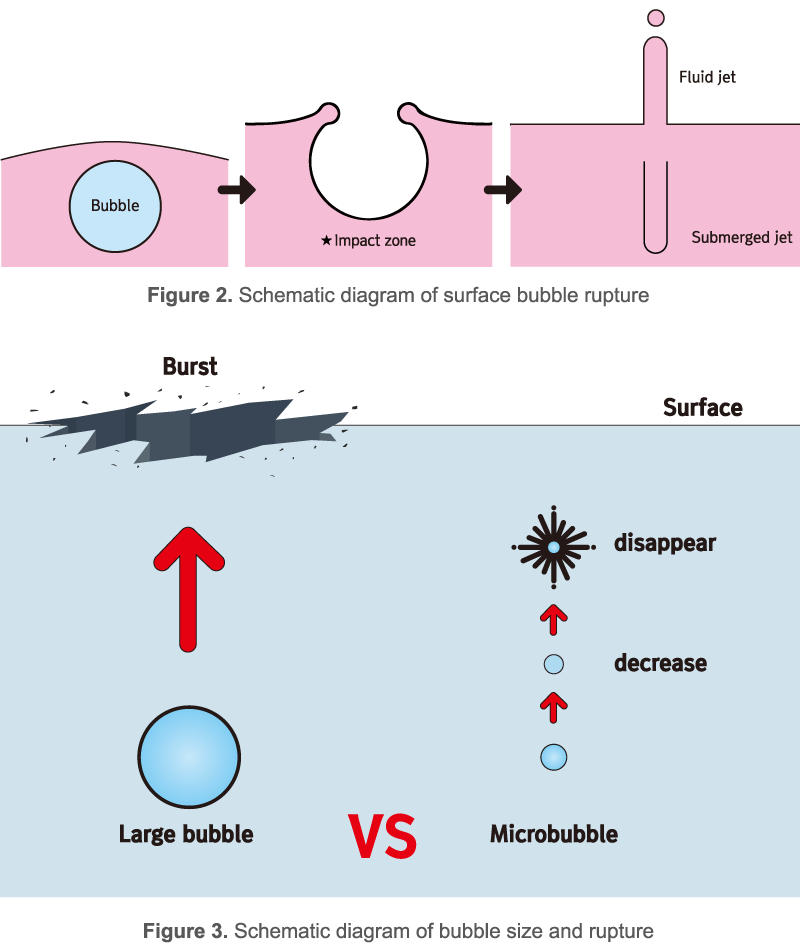

During cell culture, various mechanical actions contribute to shear stress, such as collisions, gas flow, interactions with gas bubbles, and foaming. The diagram below illustrates the rupture of air bubbles on the surface3,4.

Mechanical shear force is a primary cause of cell death in bioreactors. High shear forces can physically disrupt the cell membrane, compromising its integrity. Additionally, shear stress can inflict mechanical trauma on the cytoskeleton and other internal structures. Specifically, when bubbles burst, they create localized high shear forces that can damage nearby cells.

3 Chisti Y. Trends Biotechnol. 18(10):420~32.

4 Takahashi et al., J. Phys. Chem B 111, 1343~7.

2.3. How to reduce shear stress during cell culture

There are several approaches to reducing shear stress in bioreactors:

Bioreactor Design: The physical design of the bioreactor, especially the impeller, plays a crucial role. Traditional Rushton impellers are ideal for microorganisms with strong cell walls, whereas pitched-blade or gentler marine impellers are better suited for shear-sensitive animal cell cultures.

Gas Sparging Strategies: Controlling both shear stress and oxygen delivery is vital. To minimize gas bubble size, the combination of micro-spargers and optimal impeller RPM affects both shear stress and the oxygen transfer coefficient (kLa)5.

Chemical Surfactants: Adding surfactants such as polysorbate or poloxamer can protect cells and produce biophar- maceuticals. Polysorbates mitigate harmful interactions between therapeutic proteins and various interfaces and are commonly included in drug formulations. However, polysorbates can create foam, requiring additional anti-foaming agents and may degrade over time, posing quality concerns, and a potential risk factor for patients6.

5 Kreitmayer et al., Bioengineering, 9(5), 206.

6 Dwivedi et al., Int J Pharm. 552(1) 422~36

2.4. Benefit of poloxamers

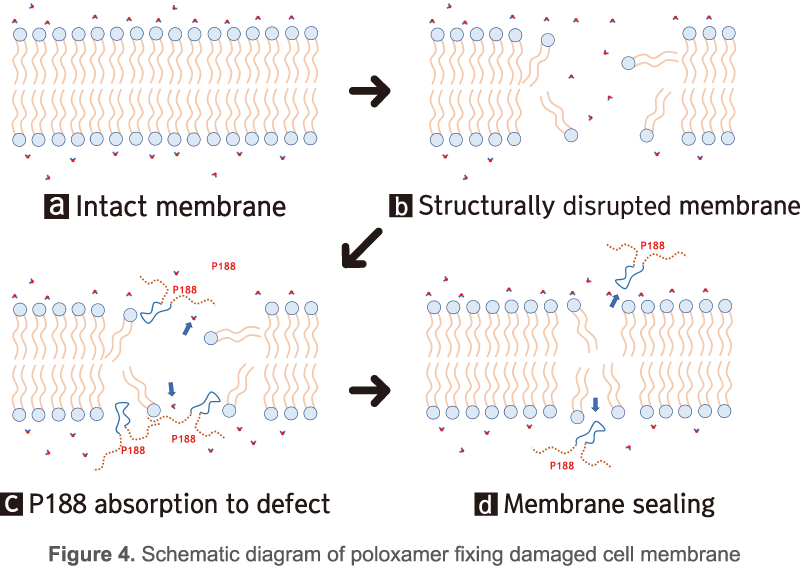

Poloxamers, particularly poloxamer 188, are commonly used as cell protection agents during bioreactor cell culture, mitigating damage from sparging and turbulence. As a surfactant, poloxamer offers several physical and biological benefits:

- Strengthens and stabilizes cell membranes.

- Reduces energy required during bubble breakage.

- Provides protective effects on cell surface receptors and signaling.

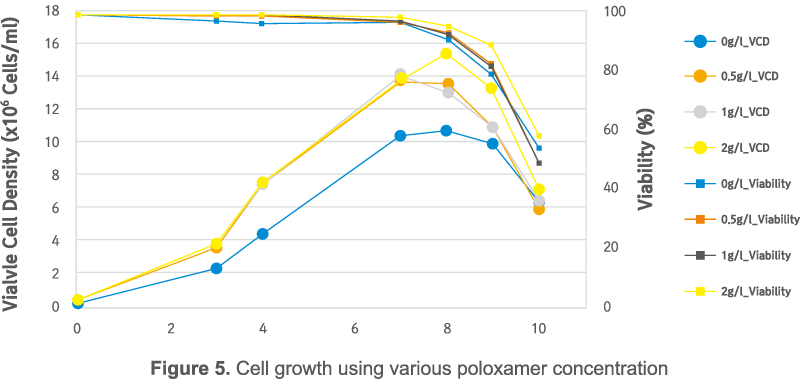

Poloxamers offer additional flexibility in bioreactor management by providing effective shear protection. While they may cause some foaming, it is relatively small and easily managed. Without a shear protectant, cell densities and process productivity are limited, especially in high-density operations like perfusion processes. Based on the previous study7,8, CELLiST Solution Center investigated the impact of various concentrations (0 to 2 g/L) of Poloxamer 188 on cell culture performance. The results of viable cell density (VCD) and viability are presented below. Overall, the addition of poloxamer significantly enhances VCD and viability of the cell culture. Depending on the cell line, concentration can be optimized, but generally should be set around 0.5-2 g/L (CELLiST guidelines recommend use of 1 g/L). Adding additional poloxamer during the culture is usually not required.

7 Guzniczak E et al., Biomicrofluidics 12(4):044118.

8 Tharmalingam T et al., Biotechnology and bioengineering. 112(4):832-7.

Due to the variability in Poloxamer 1889, it has been challenging to use it consistently as a raw material for commercial cell culture media production. However, recent advancements by Poloxamer manufacturers have ensured consistent performance. As a result, our latest CELLiSTTM media formulations, including BASAL3P, BASAL10P, and CHO MX, now incorporate Kolliphor® P 188 Bio, a high-purity Poloxamer specifically designed to minimize shear stress during biologics manufacturing.

9 Narayanappa AT et al., BioTechniques 2019 67:3, 98-109.

Attached Files

- ACK_Technical Notes Poloxamer for Cell Culture_Brochure_B_v7_240909.pdf (2.8M) 13회 다운로드 | DATE : 2024-09-23 17:25:27

댓글목록

등록된 댓글이 없습니다.

SAMPLE

SAMPLE