|

Product Basal Media

CELL CULTURE MEDIA

Ajinomoto CELLiST Korea’s CELLiST™ BASAL Media for Chinese Hamster Ovary (CHO) cell lines are developed based on Ajinomoto’s strong capabilities in amino acid technology and over 30 years of experience in the cell culture media business. CELLiST™ Media are high-performance, chemically-defined media, free from any animal-derived ingredients.

CELLiST™ BASAL Media are all Chemically Defined Media, optimized for Chinese Hamster Ovary (CHO) cells cultures and the production of recombinant proteins. CELLiST™ BASAL Media are developed based on Ajinomoto's capabilities in cell culture media development and know-how of amino acids science. CELLiST™ BASAL Media can be applied to various CHO cell lines, including CHO-K1, CHO-S, CHO-DG44 and CHO-DXB11.

| Model No. | BASAL3 |

|---|---|

| TYPE | Powder |

| Concentration | 27.0g / L |

| With Additives | D-Glucose |

| Without Additives | L-Glutamine · Sodium hydrogen carbonate · Thymidine Hypoxanthine · Poloxamer · Insulin and other growth factors |

| Storage Condition | 2℃ to 8℃, dark and dry |

| Shelf Life | 36 months |

| Item Description | Powder, chemically defined and animal derived component free medium, rehydrate to 1 L |

| Model No. | BASAL3P |

|---|---|

| TYPE | Powder |

| Concentration | 28.0g / L |

| With Additives | D-Glucose · Poloxamer |

| Without Additives | L-Glutamine · Sodium hydrogen carbonate · Thymidine Hypoxanthine· Insulin and other growth factors |

| Storage Condition | 2℃ to 8℃, dark and dry |

| Shelf Life | 24 months |

| Item Description | Powder, chemically defined and animal derived component free medium, rehydrate to 1 L |

CHO-K1 cell line

Fed-batch culture of CELLiST BASAL3 with CELLiST F7

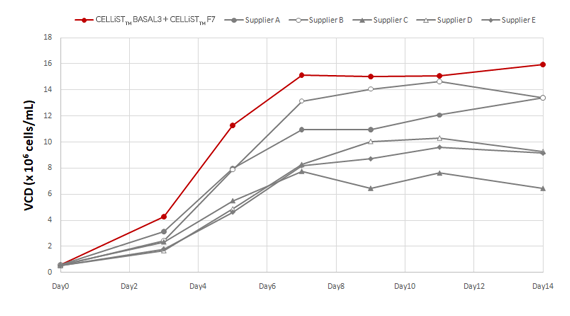

A Viable cell density

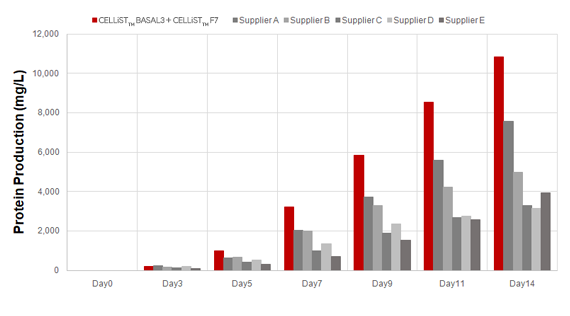

B IgG Titer (Day 14)

Figure 1: Fed-batch process was performed in an Ambr®15 microbioreactor system, using CHO-K1 cell line expressing IgG1 antibody. Feeding in CELLiSTTM group was performed at a concentration of 6% (v/v) on day 3, 5, 7, 9 and 11. ‘Supplier A, B, C, D and E’ represent basal/feed media combinations from major media suppliers. Culture and feeding manners were performed according to each manufacturer’s recommendations.

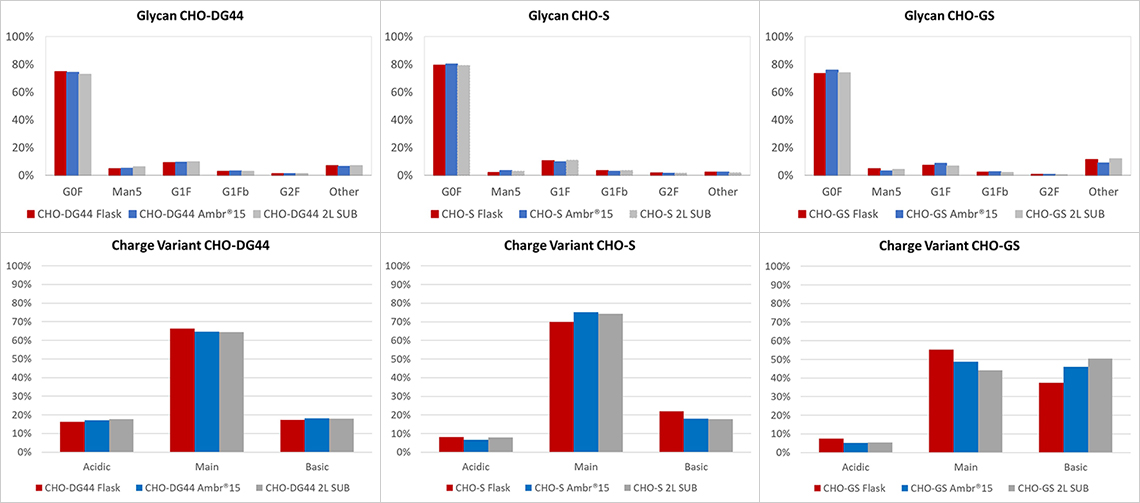

Fed-batch process was performed in 125 mL Erlenmeyer flasks, Ambr®15 microbioreactor system, and 2L single-use bioreactor system (Sartorius, BioStat® B), using CHO-DG44, CHO-S and CHO-GS cell lines expressing IgG1 antibody. Feeding was performed at a concentration of 6% (v/v) on day 4, 6, 8, 10 and 12.